Advancing chassis with Docol® AHSS

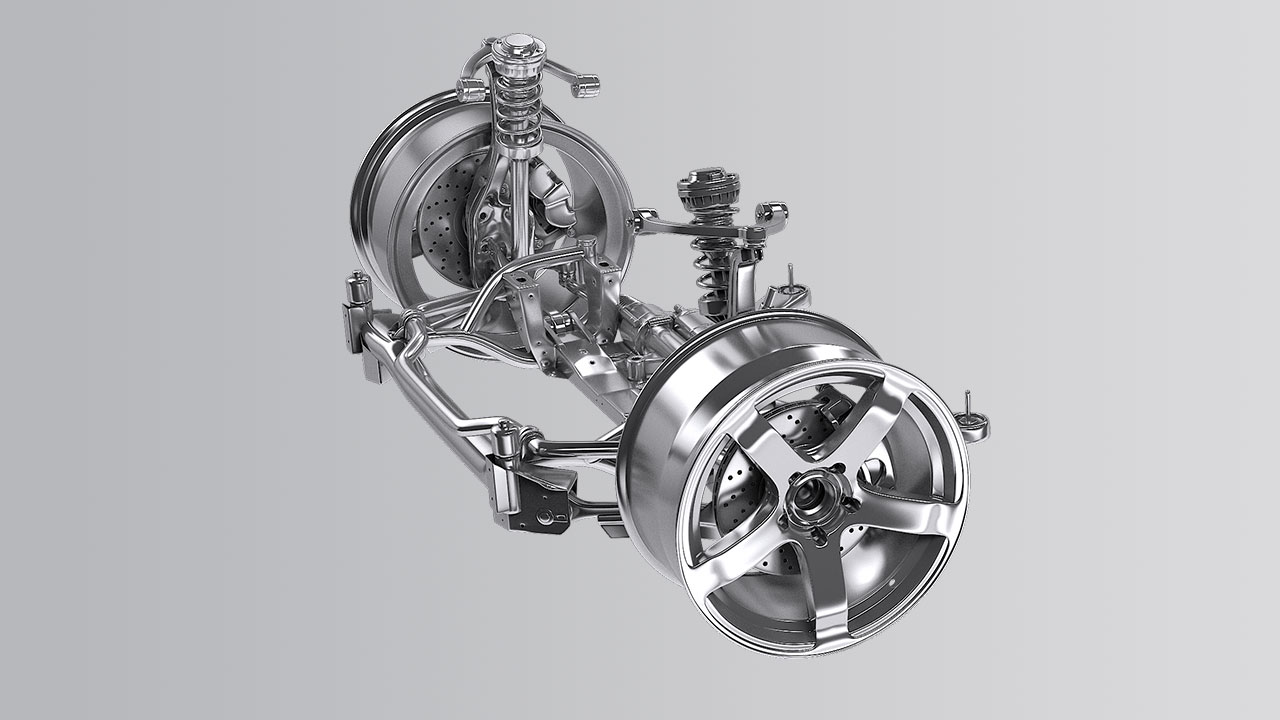

The Docol® product portfolio of hot-rolled advanced high strength steel allows for new, innovative chassis components.

The Docol® product portfolio of hot-rolled advanced high strength steel allows for new, innovative chassis components.

When it comes to chassis components, many have design properties that are in the range where hot rolled steel may be more suitable than cold rolled steel. One of the biggest reasons for this is thickness. Cold rolled steels are generally only available with thicknesses from 0.5 mm to 2.1 mm, whereas hot rolled steel products go beyond, from 2.0 up to 6.0 mm.

In addition to a wide thickness range, Docol® hot rolled AHSS makes it possible to drastically increase the tensile strength in a component, while reducing the amount of material needed to produce it. This can result in a significant reduction in weight, while achieving the same performance and a lower cost, thanks to less material needed overall.

However, the advantages of utilizing high strength hot rolled steel for chassis components like torsion beams, control arms and chassis frames goes further. High tensile strength and an optimized microstructure also give excellent fatigue properties. Strength levels up to 1200 MPa are available and steel is the most cost efficient light weight material. Overall, the complexity and high integration level that chassis require today can be solved with steel.

The state-of-the-art cooling line for hot rolled steel at SSAB allows for many more grades of hot rolled AHSS, with high consistency. Many years of adjusting and improving our hot rolled processes have led to a reputation as a quality producer.

The range of Docol® hot rolled steels is extensive, with many more grades currently in development, including steels like complex phase (CP), martensitic steel (M), press hardening steels (PHS) as well as grades with improved hole expansion and the new 3rd generations steels. Each can provide characteristics that are interesting for chassis applications.