Customer case

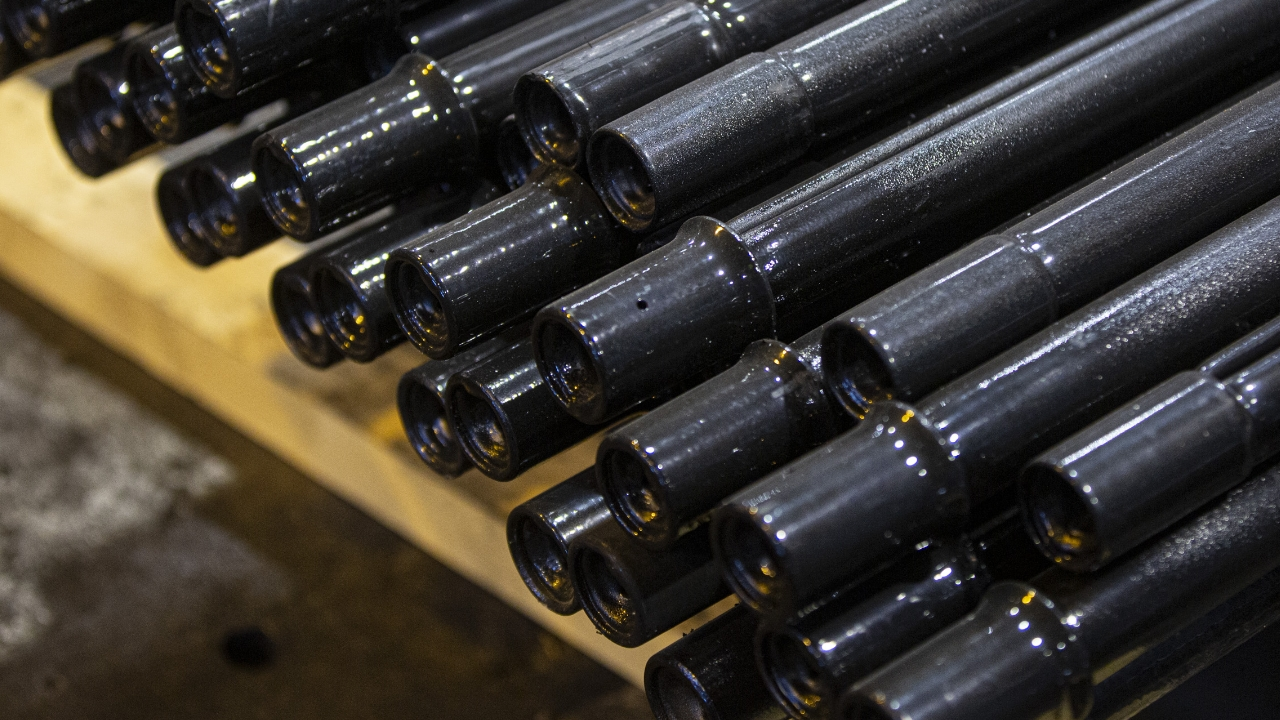

Björkdalsgruvan discovers the benefits of SSAB Virsbolt

6 min read

Case details

Björkdalsgruvan in the north of Sweden was opened in 1988 as an open-pit mine for the extraction of gold. Today it is the second largest open-pit in Sweden. In 2019 it went underground when geological surveys showed promising deposits of gold at deeper levels. The average yearly production of gold is around 1200 kg. The mine is operated by the Canadian-based company Mandalay Resources. It employs around 240 people above and below ground, and an additional 100 external contractors. Mandalay Resources also operates the Costerfield gold and antimony mine in Australia.