Wastequip revolutionizes U.S. roll-off containers with Hardox® wear plate

October 11, 2021

5 min read

Case details

Product

Hardox® 450Country

United States

Company

Wastequip

Industry

Recycling & waste processing

Brand program

Hardox® In My Body

Roll-off waste containers are notoriously abused by rough transports, precarious material handling and just downright harsh loads. For end users, having to continuously repair or replace damaged boxes means high operating costs and unplanned business interruptions.

New containers are 4 times stronger, weigh 20% less

For Wastequip, a North Carolina-based manufacturer of waste handling equipment, these problems transformed into an opportunity to fill a void in the North American market with an ultra, heavy-duty container made from Hardox® 450 wear steel.

By combining the best traits of Hardox® wear plate with the design and engineering expertise of Wastequip, the new containers offer users a light-weight option with enhanced strength and load optimization capabilities that allow haulers to carry significantly more payload than traditional steel roll-offs. Meanwhile, the added wear-resistance and durability not only provide a longer service life, but reduce the need for repairs and diminish overall costs by eliminating repeated replacements. All of these benefits result in lower operating costs and enhanced sustainability, with fewer loads translating to decreased CO2 emissions and increased fuel efficiency.

“We are constantly investigating new and better options that we can incorporate into our products to improve functionality and durability,” says Kirk Warren, Director of Product Management – Steel Division for Wastequip steel products. “These new roll-off containers, which are the first in the United States to use innovative Hardox® wear resistant steel, allow our customers to increase their capacity, efficiency and sustainability, while reducing the need for repairs, saving them time and money.”

According to Warren, Wastequip’s Hardox® wear plate version of roll-off containers are 4 times stronger than ordinary mild steel grades, while weighing 20% less and lasting twice as long as traditional heavy-duty roll-off containers.

Wastequip’s Kirk Warren, Director of Product Management and pictured at right, Jon Howley, SSAB Americas’ Environmental and Sustainability Business Development Director spearheaded a joint development project to deliver tougher containers to the U.S. market.

In a side-by-side comparison for puncture resistance and dent protection, the container built with Hardox® wear plate maintains structural integrity with less steel. Watch the test videos to see all the action.

Watch the side-by-side tests

FLEXIBILTY:

PIG IRON VS HARDOX® 450

STRENGTH:

I-BEAM VS HARDOX® 450

PUNCTURE RESISTANT:

JACKHAMMER VS HARDOX® 450

Putting the beast to the ultimate tests

With a waste container made from Hardox® 450, the opportunity to truly demonstrate the benefits meant squaring off two containers during side-by-side comparisons and pushing the container made with Hardox® wear plate to the bulging point. Watch the test series videos to see all the live action.

On a cold day in December at the SSAB Alabama mill, Jimmy Allen, Technical Development Manager, Special Steels joined Kirk Warren for this series to demonstrate puncture resistance, dent protection and flexibility. The test parameters pitted one of the mill’s containers made with Hardox® 450 and a container constructed with mild steel at a higher thickness rated for heavy-duty applications.

“Everything’s based on data,” says Warren. “So while I like what I’m hearing and I like what I’m seeing, you have to show me the proof. I’ll tell you going in, I questioned how it could really be any different. What makes it so unique? So we set up a series of tests. We did side-by-side comparisons, and it is four times stronger.”

Partners in sustainability, a story of change one waste container at a time

The journey to launching such an innovative container began with a question, when the owner of a transportation company asked how he could buy a waste container made with Hardox® wear plate. What followed was a collaborative product development project that not only drastically reduced SSAB’s Alabama mill’s waste container operating costs, but also led to the launch of an entirely new product line in the United States. Spearheading the efforts, Jon Howley, Environmental and Sustainability Business Development Director for SSAB Americas and Wastequip’s Kirk Warren worked with their respective teams to bring about significant change.

“For us, there was a need to reduce costs and the environmental impact with a more sustainable option over rented containers,” explains Howley. “The cost associated with the rental of containers was estimated at about $465K per year, not including ongoing maintenance and repair on those types of containers.”

For Wastequip, it meant taking an industry lead. The hard and tough properties of Hardox® wear plate are well known in America’s transportation industry, however, the material had yet to be fully adopted by waste container manufacturers. It’s been used in the U.S. in truck bodies for years,” Warren explains. “The strength is known; it was just never taken into the container side of the business. Those cans are being subjected to extremes, so since SSAB manufactures high tensile strength steel branded Hardox® wear plate, it seemed like a no-brainer that maybe we should look at a new design that would solve their problem and maybe come up with a new product for the market.”

After looking at the economic, social and environmental sustainability factors, both companies engaged with engineering support and collaboration to complete the project. Today, SSAB’s Mobile mill employs a fleet of 15-, 20-, 30- and 40-yard models and a vacuum container made of a Hardox® wear plate to properly remove waste and debris from the operation at a fraction of the former cost.

Plus, Hardox® In My Body member Wastequip, launched its new ultra-heavy-duty roll-off container, known as RockBox, made of Hardox® wear steel and approved as a Hardox In My Body verified product, showing the sign of quality and assuring end users that their containers meet the highest quality standards. Each application with the sign attached has passed a strict quality control evaluation and is approved as a premium product. Specialists within wear and structural technology carefully analyze each application regarding welding quality, manufacturing process and design. The sign of quality with premium ingredients assures users of value. Additionally, each sign has a unique ID that is traceable and can secure the origin and material.

Explore the benefits of Hardox In My Body equipmentWatch the full story and see how sustainability is closer than ever.

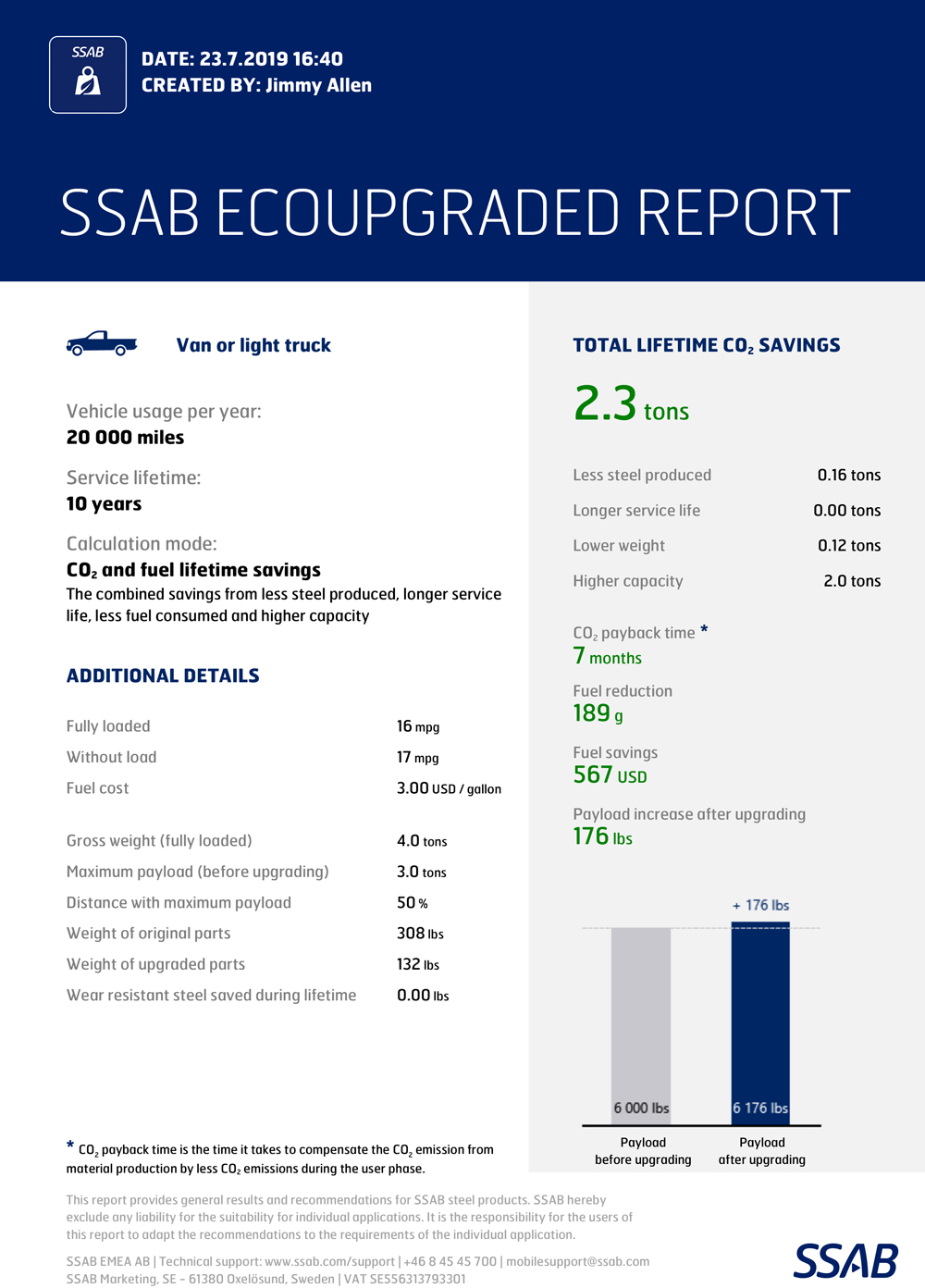

EcoUpgraded mobile app defines environmental benefits

SSAB invests in sustainable processes and employees look for continuous improvements. With the container project, engineers were able to also use the company’s proprietary mobile app to calculate the project’s potential savings.

“The sustainability feature, or attribute to load optimization, would be the reduction of loads leaving the facility,” explains Howley. “This is directly associated with the social aspect which would reduce overall emissions related to transporting the material, and it also plays a part in sustainability in the attribute of environmental. We also reduced the weight on average of the containers between 25% and 30%.”

For example, upgrading the design for a 40-yard container made from mild steel to one built with Hardox® wear plate, increases the payload by 2 tons, reduces CO2 emissions by 87 tons and reduces fuel consumption by more than 7,000 gallons over a 12-year service life. For more details, refer to the graphic showing the calculation results from the EcoUpgraded mobile app, which is available for download from both app stores.

Get an estimate of potential savings in a snap with the EcoUpgraded appCertainly not the average roll-off waste container in North America

For end users in the U.S. and Canada who change from mild steel options to containers made with Hardox® wear plate, the savings and benefits are clear.

“It’s not just a roll-off container,” says Warren. “It’s a high tensile strength steel roll-off container. We’re talking four times stronger, 20% lighter and it’s going to last twice as long. There’s less downtime, fewer repairs and users don’t have to keep buying equipment. It’s key to get it in the right application and for an extra heavy-duty application, it’s a no brainer.”

To learn what this steel can do for you, email questions to: [email protected].

I'd like my own design consultation with SSAB's experts

Today, a full fleet of containers made with Hardox® wear plate is in operation at SSAB’s Alabama mill. Removing rentals means a more sustainable way of working with a cost savings of $465K.